Tools Of The Trade

One of the most commonly asked questions by aspiring modder’s and noobs alike.

“what are the basic tools / equipment do I need to get or buy, if I want to start into case modding as a hobby?”Well look no further. Here’s a short list of the most common tools used for modding. Together with a simple description of their applications and uses.

TOOLS:

- Rotary tool

- Power Drill

- Jigsaw

- Nibbler

- Pop Rivet Gun and Blind Rivets

- Straight and Round Files

- Combination Square and Ruler

- Heatgun

- Holesaw

SAFETY EQUIPMENT:

As a General rule. “always practice safety first” Take precaution when handling any kind of power tool. Modding is no fun when you lose a limb, finger or worst an eye in the process

- Respirator Mask / Dust Mask

- Protective Eye wear:

- Earmuffs

- Utility Gloves or Cotton Gloves

- Cobra Energy Drink

Meet The Dremel

Here’s a primer on one of the most popular tool used in case modding. Meet the DREMEL.

A rotary tool is a hand held power tool with a variety of rotating accessory bits and attachments that can be used for cutting, carving, sanding, polishing and many other applications.

The smaller rotary tools use high RPMs to maintain the correct cutting conditions for the tool bits. They have low torque which makes them safer for freehand use than the larger higher powered models or similar power tools. A wide variety of accessories are available for applications such as cutting, carving,sanding, polishing, and grinding. The carving (or cutting) bits are referred to as burrs and are similar to those used by dentists.

Rotary tools are sometimes called a “Dremel” because of the market strength of Dremel, a particular brand. But the Dremel name is still protected and is far from legally genericized.

source: wikipedia

As with other hand held power tools. Always consult your user’s manual for the proper use and operation of your power tool. Try to familiarize yourself with all the controls and features of the power tool your using. Always wear proper safety gear when using your power tool.

In this quick tutorial I’ll be using my Dremel 300 rotary tool, 1″ standard emery cut-off discs, Dremel 1/2″ sanding drum attachment and a straight and round file later for cleanup work.

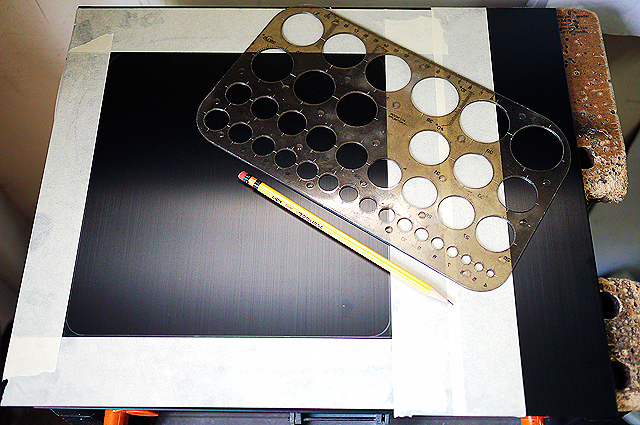

Step 1: Marking and masking. Start by making guide lines on the material your cutting. You can use a pencil in making the guide lines. After marking the line, I recommend covering up the outside of your cutting line with masking tape. This protects your material or panel from unwanted scratches while cutting.

I’m also using my circle template to add corners on my window design. I prefer to use the circle template because it is more accurate and you can choose different diameter sizes.

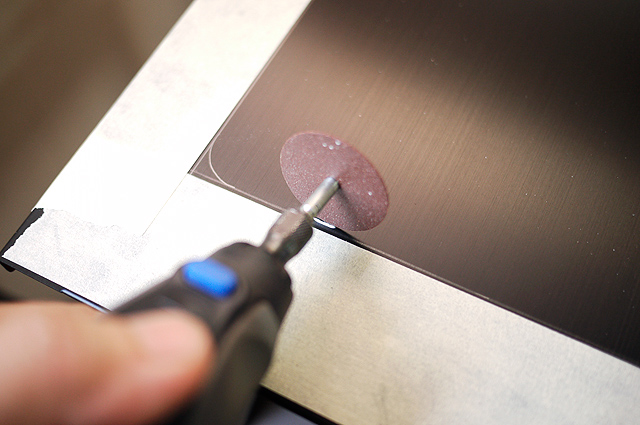

Step 2: Cutting straight lines. I prefer to use the 1″ ordinary cut-off disc, simply because they are cheaper, cuts faster and more accurate than the reinforced cut-off discs. When cutting straight lines simply guide the tool on the inside of your cutting line. Do not force the cutting disc to make the cut. You’ll end up wasting your cutting discs or worse break it in the process.

Do not throw away your worn out cutting discs, you’ll be needing them later on when cutting the curved corners.

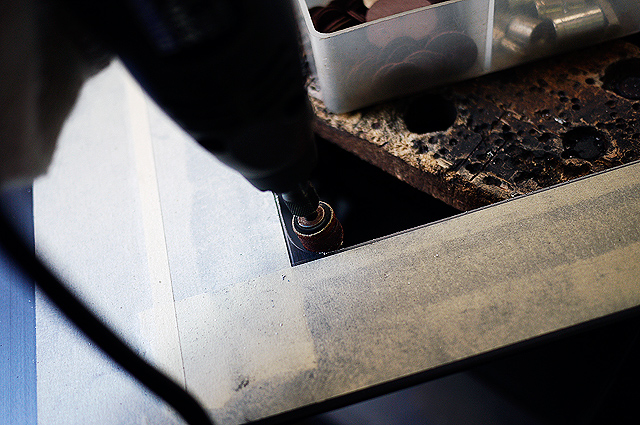

Step 3: Cutting the corners. This is where the smaller cutting discs come in. You’ll notice that the rounded corners have smaller diameters. Using the smaller cutting discs tilt your Dremel or rotary tool to a 45 degree angle and slowly guide the cutting discs to cut the corners. This is a bit tricky and requires a bit of practice. But with a lot of patience and practice you’ll be doing perfect cut corners in no time at all.

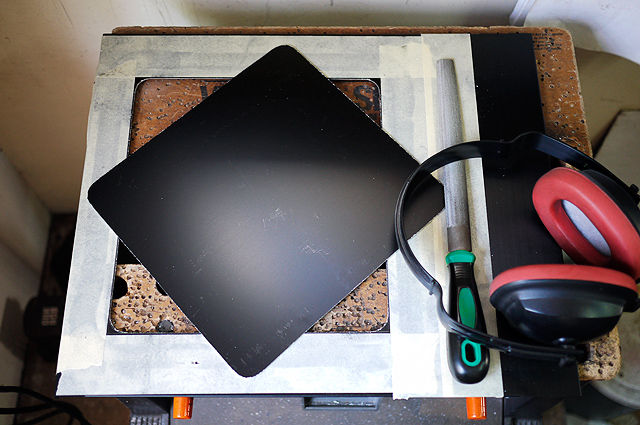

After a few minutes of cutting here’s the result.

Step 4: Filing and Sanding. The Dremel or rotary tool leaves minor machining marks and requires very little cleanup work. All you need is a straight file to clean the edges and round file for the rounded corners. Alternatively you can use 1/2″ sanding drum attachment included with your rotary tool kit.

Cleaning up the corners using a round file.

Cleaning up the corners using the 1/2″ sanding drum attachment.

Remember to leave the masking tape on until you’re finished cleaning up the edges and corners. Hopefully you’ll end up with something like this or even better

I hope you enjoyed reading this quick guide and tutorial. Always remember practice and patience is key. Happy Modding!

Source: Rig Noobies Modding 101 Part 1 and 2

Very very nice article Sir, very useful and practical and useful information. How about car body repair and simple maintenance such as making the car shiny and maintaining the body? Hehehe.

ReplyDeleteIt could help a lot of people to save on repair costs. Of course, it would be most helpful to know where to buy the best tools at the most efficient cost.

More power.